Lateral Cutting

We offer a Direct, Contract or Sub-Contract Service on all lateral drain cutting work across the UK.

Datomic Lateral Cutting have the equipment you need to solve drain blockage issues fast. Lateral Cutting is a tried and tested method for removing obstructions from the drainage system without having to disrupt the pipe system by fully excavating. The lateral junctions of the drainage system that connect pipes from areas such as toilets are cut using specialised equipment clearing obstructions. This is a safe and secure way of removing blockages.

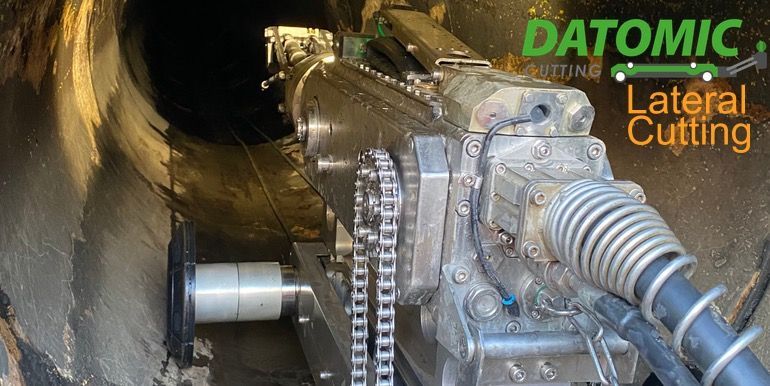

Datomic use only the finest, German engineered robotic equipment for lateral cutting that is recognised and respected across the industry for its power and performance. Our remotely operated cutters can be deployed at over 100 metres from a single entrance point, with constant CCTV monitoring to diagnose the problem, milling heads that can cut precisely positioned laterals for connecting pipes, and powerful grinding capabilities to cut through steel bars, collapsed liners or any other obstruction.

Lateral Cutting Explained :

Lateral cutting in drains and sewer systems is a recognised (No Dig) technique used to remove blockages that are restricting flow, such as tree roots or hard debris, from lateral sewer or drain lines without the need for extensive digging. This usually involves inserting a specialised lateral drain cutting tool, hydro, pneumatic or mechanical remote robotic robots equipped with precision cutters. This remote cutting technique is commonly used in the drainage line maintenance to clear roots or hardened deposits, limescale, concrete or cement while minimising disruption.

Datomic robotic lateral cutters are fully supported by cctv with a 360 degree camera used for cutting precision. Lateral drain cutting is often preferred over traditional excavation due to lower costs and less invasive and faster resolution to drain issues.

When would be the best deployment of Lateral Drain Cutting ?

• Blockages - Lateral drain cutting is effective for clearing blockages in lateral connections and drain linings caused obstructions.

• Maintenance - Regular lateral cutting can prevent future blockages and maintain drainage system functionality.

• Repair - Lateral cutting is used for drainage repair services, and down branch pipe cutters often used in conjunction with pipe linings

Key features and benefits of Lateral Cutting:

• Lateral Cutting is Non-invasive which allows for pipe repairs without digging up the earth or disrupting property.

• Lateral Cutting is accurate so this always ensures precise cutting and shaping of openings.

• Lateral Cutting can remove blockages, roots, and other obstructions, restoring drainage system functionality vs other no-dig repair techniques.

• Lateral Cutting is accurate when used in reopening lateral pipe connections after relining or repair work.

• Lateral Cutting is often used to remove encrustation and build up from within pipes.

Lateral Drain Liner Removal

This is a process that involves cutting away the lining of a lateral pipe to reopen connections after repair or relining. Lateral cutting is a specialised technique used to clear blockages and obstructions in lateral connections of drainage systems. These connections link pipes from various sources, such as toilets, drainage, gutters other fixtures to a main sewer line.

This work is often split into differing types of Lateral Cutting :

Smart Cutters | Twist-on Cutters | Remote Lateral Cutters

Operated remotely by experienced skilled teams, these robotic cutters are ideal for reopening connections to drain pipes and removing solid obstructions.

Lateral Cutting Robots

Our Service: Lateral Cutting Capabilities

Remote robotic cutter is state of the art ‘climbing robots’ that enable us to cut at elevated locations and negotiate difficult bends, making previously inaccessible obstructions accessible. These cutters are specifically designed for smaller diameter pipework, from 75mm up to 225mm.

These lateral cutter robots are the latest technology and offer :

- Pneumatically powered milling motor

- Self-cleaning LED camera for constant monitoring

- ‘Climbing’ abilities for hard-to-reach areas

- Portable equipment for internal and remote works

- Employs a range of precision milling heads to suit the job

The precise nature of our lateral cutting process using the milling tool provides confidence that minimal damage is incurred to the host pipe and all works can be completed to a high level of accuracy. From reopening lateral connections to removing steel bars, we have extensive experience in these projects .

Emergency Lateral Cutting Nationwide

The majority of Lateral Cutting is provided by air driven systems and benefits from all associated airlines being contained in an umbilical hose, making the system very robust and user friendly. The control box houses a regulator and lubricator allowing this machine to work in all climates.

alongside motor extensions to allow the cutter to work in larger pipes we have the ability to offer battery and air driven cutting.

Lateral Cutting technology offers all the tools you would need including:

- LED pan and tilt camera unit with self-cleaning features

- Battery operated milling motor for minimal noise pollution

- Powerful self-propelling robot for long-range cutting works

- Portable options available for remote working

- Full range of motion with complete control over the milling process

Robotic lateral cutter equipment is designed for cutting away concrete and other hard or cementitious and organic based material from within drain pipe sections.

Commercial Drain Lateral Cutting Services and Lateral Drain Flow Reinstatement

Robotic Drain Lateral Reinstatement Cutters have CCTV capability and are remotely-operated, waterproof devices are inserted into piping and moved to the rough position of the pre-existing laterals. The CCTV is used to identify any bulging or defects where the lateral opening is located, robotic cutter then have the ability to cut a hole in the new pipe with a milling bit. Once a lateral line is opened allowing wastewater flow, the cutter is removed and then reinserted with a wire brush attachment to file down the polyurethane to fully open the lateral line.

Lateral cutting tools have small but, extremely powerful cutter locates the exact position of any junction by cutting through the liner from the branch side. The cutter quickly and easily opens up a hole in the liner in exactly the right position.

Depending on the access, these tools can either totally re-open the connection giving a perfect finish or if access is very tight it can simply open a small hole. This will allow a lateral cutter to re-visit at a later time and fully open the connection. Both sizes of the DTB can also be used to root cut, using a high tensile wire cup brush.

24/7 Lateral Cutting Specialists

How it works: Lateral Cutting for Drains and Sewers

The robotic lateral cutter is inserted into the mainline sewer or drain underground and advanced toward the lateral connection that is located via a coordinated measurement. The lateral cutter makes an initial hole to relieve any flow that may have accumulated in the lateral and to help remove the remainder of the lining material from the lateral opening so, the lateral flow can be reconnected. Datomic deploy industry leading equipment to solve your problem. All are battery or pneumatically operated for maximum range, flexibility and performance to resolve any type of blockage or obstruction that could be restricting lateral flow.